can low carbon steel be hardened Color case-hardening high-carbon steel.

There are numerous engineering materials available today, each with its distinct properties and applications. One such material that has stood the test of time is high-carbon steel. Renowned for its strength, toughness, and durability, high-carbon steel has been used in numerous industries for centuries. In this post, we will explore the fascinating process of color case-hardening high-carbon steel and the precision shafts made from 1566 carbon steel.

Color Case-Hardening High-Carbon Steel

Color case-hardening is a specialized heat treatment process used to increase the surface hardness of steel while maintaining its toughness in the core. This process has been employed for centuries to improve the wear resistance of various steel components, such as firearms, knives, and gears.

The color case-hardening process usually begins with a low-carbon steel or iron object. The object is heated in a specialized furnace to a specific temperature and then exposed to a carbon-rich environment. This environment can include materials like charcoal or bone, creating a carbon-rich atmosphere. The object is left in this environment for a prolonged period, allowing carbon molecules to diffuse into the surface layer of the steel.

As the carbon atoms diffuse, they interact with the iron atoms in the steel, forming new compound layers. These compounds give the steel its characteristic colors, ranging from deep blues and purples to vibrant yellows and golds. The colors are a result of the thickness and composition of the compound layers formed during the diffusion process.

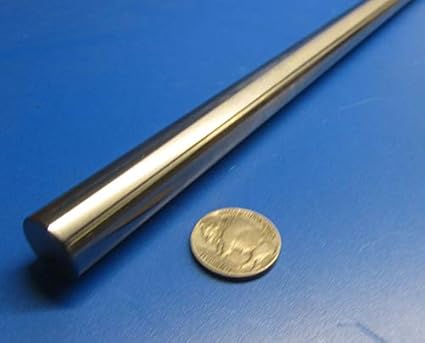

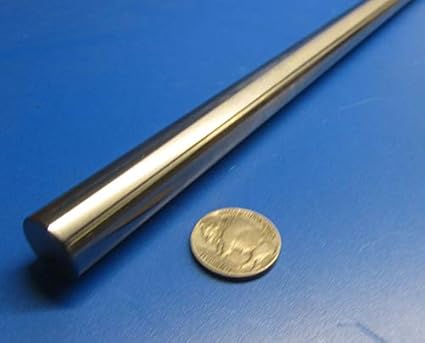

Precision Shafts made from 1566 Carbon Steel

1566 carbon steel is a high-carbon steel alloy known for its exceptional strength and hardness. It is often preferred for applications that require a combination of toughness and wear resistance, such as shafts found in precision machinery.

The precision shafts made from 1566 carbon steel are widely used in various industries, including automotive, aerospace, and manufacturing. These shafts are meticulously engineered to provide optimum performance in demanding environments.

The precision shafts made from 1566 carbon steel are widely used in various industries, including automotive, aerospace, and manufacturing. These shafts are meticulously engineered to provide optimum performance in demanding environments.

The manufacturing process of precision shafts begins with the selection of high-quality 1566 carbon steel. The steel is then carefully forged or machined to create the desired shape and dimensions. After the initial shaping, the shaft undergoes a series of heat treatment processes, including quenching and tempering, to enhance its mechanical properties.

The quenching process involves rapidly cooling the shaft to room temperature from a high temperature. This rapid cooling helps to achieve the desired hardness by transforming the microstructure of the steel. The tempered shaft is then reheated to a specific temperature to reduce internal stresses and increase toughness, resulting in a balanced combination of hardness and ductility.

Once the heat treatment process is complete, the precision shafts are meticulously inspected for dimensional accuracy and surface finish. They undergo rigorous quality control measures to ensure they meet the highest standards of performance and reliability.

Conclusion

In conclusion, the color case-hardening of high-carbon steel and the precision shafts made from 1566 carbon steel demonstrate the versatility and durability of this remarkable engineering material. Whether it is achieving beautiful colors through a specialized heat treatment process or creating robust precision shafts for critical applications, high-carbon steel continues to be a top choice among professionals in various industries.

By understanding the unique properties and manufacturing processes associated with high-carbon steel, engineers and designers can make informed decisions when selecting materials for their projects. With its exceptional strength, toughness, and wear resistance, high-carbon steel has proven time and again to be a reliable and valuable resource in the world of engineering.

If you are looking for Why is Low Carbon Steel Unresponsive to Work Hardening? - Pipingmart Blog you’ve came to the right place. We have 5 Pictures about Why is Low Carbon Steel Unresponsive to Work Hardening? - Pipingmart Blog like Why low-carbon steel cannot be hardened?, 1566 Carbon Steel Hardened Precision Shaft, 5/8" Diameter x 36" Long, 1 pc.: Amazon.com and also COLOR CASE-HARDENING HIGH-CARBON STEEL. - YouTube. Here it is:

Why Is Low Carbon Steel Unresponsive To Work Hardening? - Pipingmart Blog

www.pipingmart.comhardening unresponsive

www.pipingmart.comhardening unresponsive

COLOR CASE-HARDENING HIGH-CARBON STEEL. - YouTube

www.youtube.comcase hardening steel carbon high

www.youtube.comcase hardening steel carbon high

Why Low-carbon Steel Cannot Be Hardened?

blog.thepipingmart.com1566 Carbon Steel Hardened Precision Shaft, 5/8" Diameter X 36" Long, 1 Pc.: Amazon.com

blog.thepipingmart.com1566 Carbon Steel Hardened Precision Shaft, 5/8" Diameter X 36" Long, 1 Pc.: Amazon.com

www.amazon.comDifference Between Low Carbon Steel And High Carbon Steel | Compare The Difference Between

www.amazon.comDifference Between Low Carbon Steel And High Carbon Steel | Compare The Difference Between

www.differencebetween.comkeluli karbon tinggi sains cutting rendah

www.differencebetween.comkeluli karbon tinggi sains cutting rendah

1566 carbon steel hardened precision shaft, 5/8" diameter x 36" long, 1 pc.: amazon.com. Why low-carbon steel cannot be hardened?. Keluli karbon tinggi sains cutting rendah